What is an actuator?

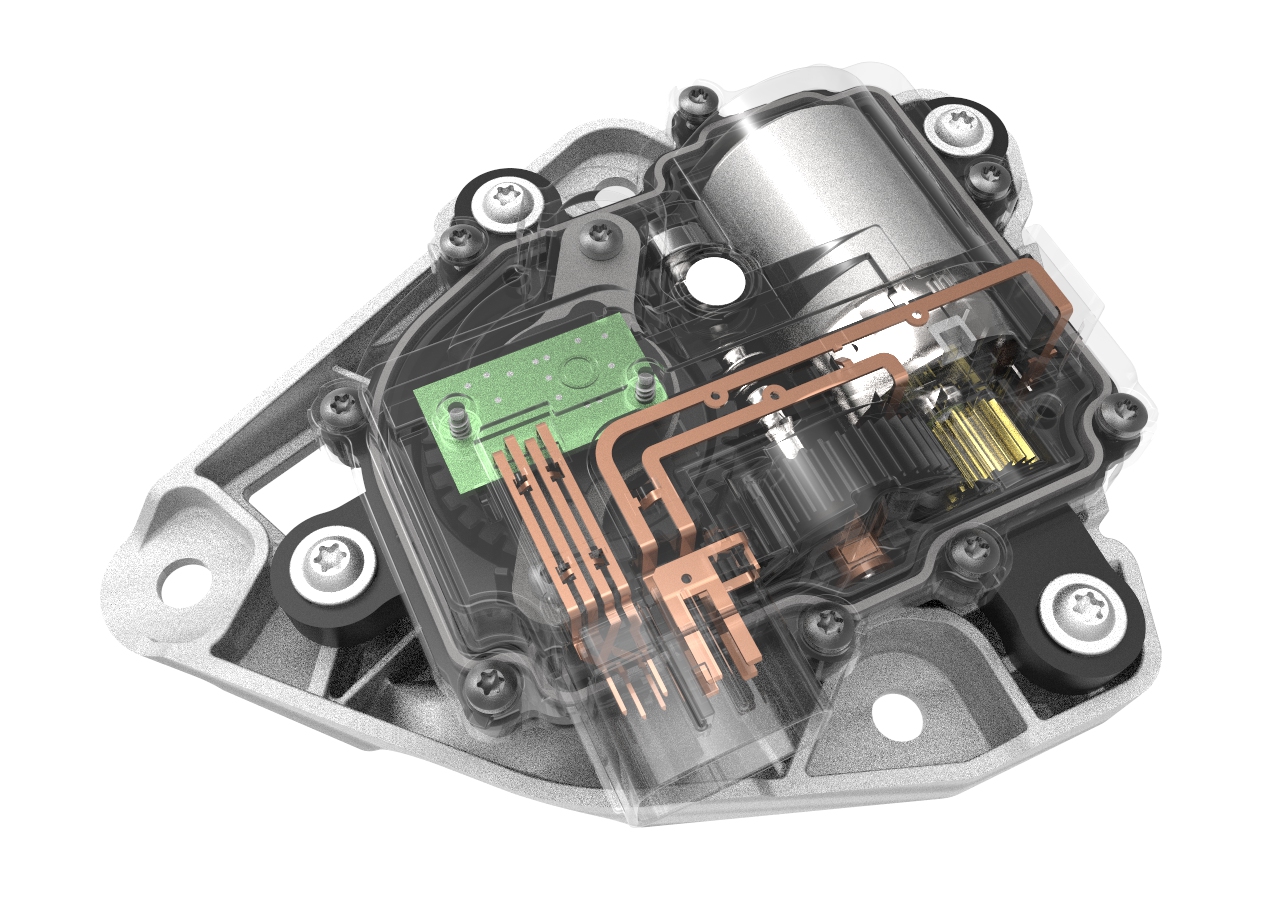

Actuator is an electromechanical device, formed by DC electrical motor, an optimized mechanical transmission and an electronic control unit, communicated with the vehicle by CAN, LIN, PWM interface.

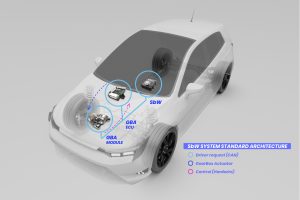

The traditional mechanical shifter system with cables or rod are replaced by electronic Shift-by-wire mechanism and actuator in the gearbox saving weight, space and improving interior design.

GEARBOX ACTUATOR AND ITS ECU, GBA

The Shift-by-Wire system uses a small and compact electromechanical device that moves the gearbox axis with the required speed and effort to change gear.

- Short response time.

- Wide torque range available.

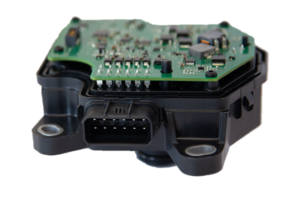

To ensure the device performs correctly, the system is designed with a standard electronic control architectures hardware / software (ECU) and already be validated by Ficosa following the latest directives in ISO 26262 Functional Safety. The ECU can be integrated or in a separate box and allows different configurations.

- Available with Embedded either Remote ECU.

- Full Diagnostics.

- Cybersecurity protected.

- Up to ASIL D FuSA Coverage.

- Autosar 3.X Software Architecture.

- CAN HS and CAN FD Communications.

Ficosa as a Tier 1 supplier developes and manufactures actuators and integrated control software, including non-contact sensors, power electronics, and thermal dissipation elements, for Automatic Sequential Transmissions and Double Clutch applications, from traditional propulsion vehicles to hybrid and electric power source.

PARK LOCK ACTUATOR, PLA

The Park lock actuator remotely and safely lock the vehicle movement in the transmission. It´s mainly used in hybrid vehicles HEV and particular for electric vehicles BEV.

The Ficosa´s Park Lock actuator integrates the ECU, embedded electronics, that together with the command, shifter or switch button, in the cockpit allows the driver to immobilized the vehicle.

- Harsh environment.

- Tightness proven.

- Short response time.

- Wide torque range and travel.

- Developed and Validated following ASPICE 3.1 Process.

- Embedded ECU with extended Temp Range Components.

- Full Diagnostics.

- Cybersecurity protected.

- Up to Three CAN Lines, HS and FD.

- Autosar 3.X Software Architecture.

- Reusable Libraries for all Model Based Software Components.

- Functional Safety full coverage up to ASIL D.

- Triple Redundancy in Position Sense, with Real Time Temperature and Current Sense, to Achieve Self-Adaptative high accuracy Close Control Loop.

- Available Applications with DC Motors and BLDC Motors.

UNIVERSAL GEARBOX ACTUATOR

- Robotised AT/TCT/DCT/DSG gearboxes, witha reduced Intrusive Safety System

- Complete Shift by Wire System approach (SbWshifter+ ECU + GBA)

- No mechanical links between the driver and the gearbox (hence no NVH transmission, the same HMI effortin all conditions, freed)

- Weight reduction> -30% vs. traditional Bowden ATX Systems